At ANSS Consultant & Services Corp., our Chemical Division is dedicated to

delivering high-performance,

sustainable chemical solutions tailored to meet the demanding needs of industrial,

energy, and

environmental sectors. In collaboration with strategic partners, including global

leaders like PSI

Global Solutions, we bring cutting-edge chemistry to optimize operations, reduce

costs, and support

regulatory compliance.

Our offerings are built around innovation, efficiency, and environmental

responsibility, ensuring that

every chemical solution we deliver integrates seamlessly with your existing systems

and enhances your

overall process performance.

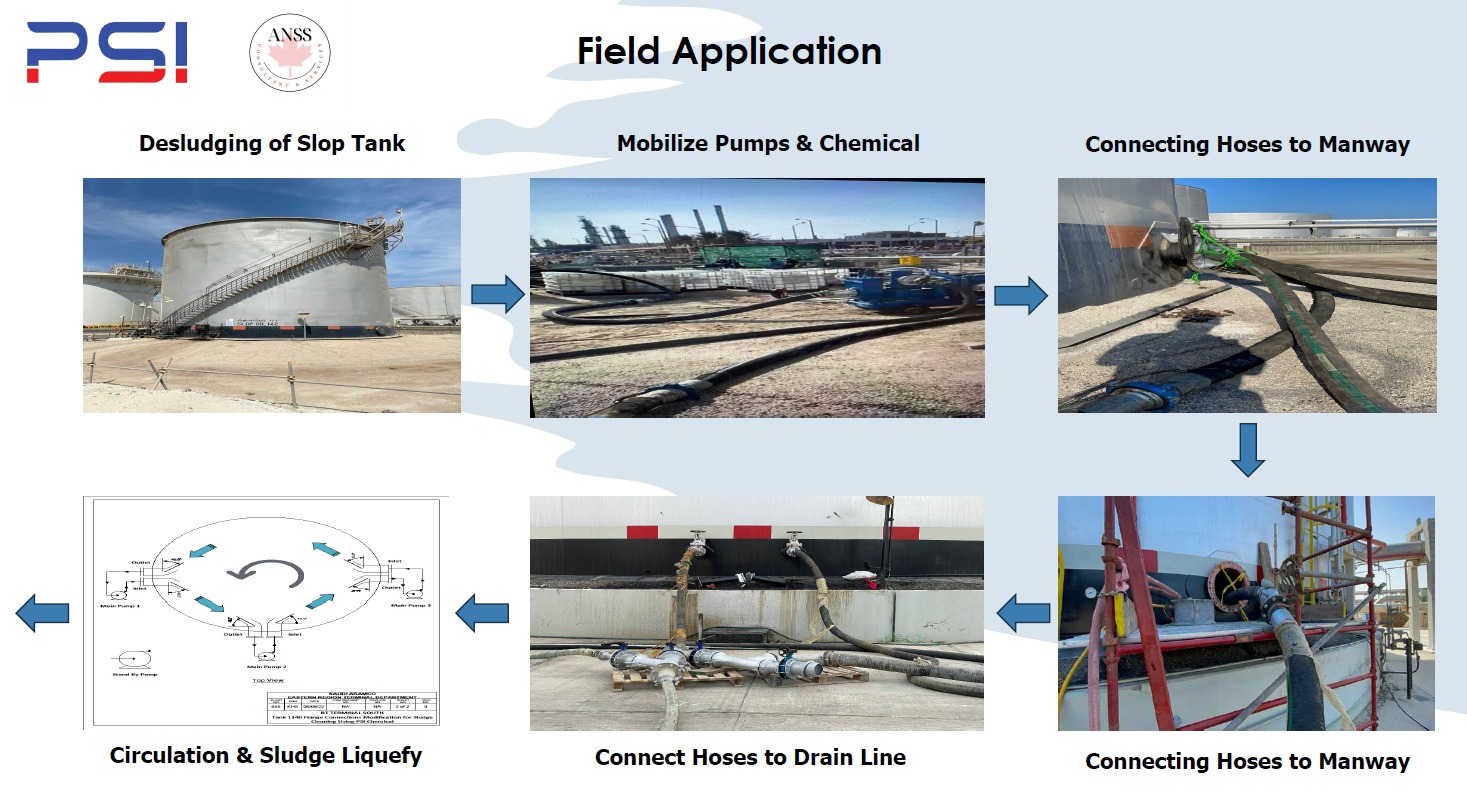

1. Desludging & Oil Recovery Solutions

PSI chemistry is a proprietary blend that enhances several oil and gas applications

and processes. It is an anionic formulation with an affinity to attract to negative

surfaces. I’m pleased to share that PSI is approved by SAUDI ARAMCO and ADNOC, and

the approval process is currently underway with PETROLEUM DEVELOPMENT OMAN (PDO) and

THE BAHRAIN PETROLEUM COMPANY (BAPCO).

Applications:

- Crude Oil Tanks

- Slop Oil / Black Oil / Heavy Fuel Oil Tanks

- Desalters & Dehydrators

- Separators & Other Production Vessels

- Flowlines & Pipelines – including fully clogged and non-piggable lines

PSI will disperse and release Wax, Asphaltene, and Sand deposits in the sludge,

liquefying it into a pumpable form, which significantly eases the cleaning process

and minimizes the time required to clean tanks and vessels. Solids and liquids will

be separated. Being water-soluble, PSI will not travel in the oil phase but will

precipitate out in the water phase, without influencing the oil properties. PSI's

unique ability to break the bonds of interfacial surface tension between solids and

liquids enables production equipment to operate within its designed range, resulting

in a cleaner and more efficient process while maintaining a safe and environmentally

responsible working environment.

Highlights:

- Sludge depositions are gradually liquefied molecule by molecule, so no chunks of

solid sludge flow downstream.

- Hydrocarbon gets broken down into hydrocarbons.

- Salts and other solids drop into the water phase.

- PSI solution drops into the water phase.

- No influence on the chemistry of liquid – oil – Compatible with Hydrocarbons.

- Significantly minimizes time for desludging.

- 95% of oil sludge is recovered back into the oil stream.

- Integrates with the existing scope of work of the user with minimal changes in

the current cleaning program.

We are proud to highlight PSI proven track record in successfully executing

large-scale desludging operations for major clients like Saudi Aramco, with projects

involving high-capacity crude and slop oil tanks. These projects were completed

safely, efficiently, and within remarkably short timelines, demonstrating the speed

and reliability of our PSI chemistry in real field conditions.

- • Successfully desludged a 90,000-barrel dry crude tank (Tank ID 369 T-5)

with 650

m³ of sludge in just 4 days at Aramco Safaniya GOSP-1.

- • Completed desludging of a massive 1.25-million-barrel wet crude tank (Tank

ID

60-3945) containing 5,000 m³ of sludge in 40 days at Aramco Ras Tanura North

Terminal.

- • Cleaned a 10,000-barrel slop oil tank (Slop Oil 142) with 125 m³ of sludge

in

only 5 days at Aramco Ras Tanura Refinery.

- • Removed 5,500 m³ of sludge from a 300,000-barrel slop oil tank (Slop Oil

145) in

21 days at Aramco Ras Tanura Refinery.

- • Efficiently desludged a 500,000-barrel wet crude tank (Tank ID 60-1140)

with

1,300 m³ of sludge over 30 days at Aramco Ras Tanura South Terminal.

Get in Touch:

To proceed with a tailored solution, we would appreciate it if you could kindly

provide the following details:

- • Crude API gravity – to assess viscosity and sludge behaviour.

- • Tank bottom slope orientation – is it sloped from center to shell, or

shell

to center? This affects the drainage strategy.

- • Tank size – diameter and height (or total volume in m³/barrels).

- • Estimated sludge volume – to calculate chemical dosage and cleaning time.

- • Number and size of dewatering lines – to evaluate fluid management during

treatment.

- • Current desludging practice – e.g., manual entry, jetting, circulation,

steam, or mechanical removal.

Once we receive this data, we can provide a detailed proposal that includes a

chemical strategy, circulation plan, and estimated time for cleaning.

2. Water & Wastewater Treatment Solutions

We provide innovative chemical treatment programs for industrial and municipal

wastewater systems—

targeting the removal of contaminants, optimizing biological performance, and

enhancing sludge

dewatering.

- • Customized Catalyst Beds for advanced oxidation and effluent treatment

- • Electrochemical Oxidation & Enhanced DAF Systems

- • Flocculants, Coagulants, and pH Conditioners tailored to system needs

- • Filter Press & Screw Press Dewatering Additives

- • Integration with biological and hybrid systems:

- - MBR (Membrane Bioreactor)

- - MBBR (Moving Bed Biofilm Reactor)

- - ASP (Activated Sludge Process)

- - Fenton and Advanced Oxidation Processes

- • Chemical dosing optimization to improve BOD/COD removal and system reliability

Why Choose ANSS Chemical Solutions?

- • Performance-Driven: We use data-backed assessments to ensure

maximum impact.

- • System-Compatible: Our chemicals are tailored to your

existing infrastructure.

- • Eco-Friendly: All formulations prioritize safety, compliance,

and environmental stewardship.

- • Field-Tested: Our technical team provides on-site evaluation,

pilot trials, and commissioning support.